Welcome to our comprehensive guide on CSI Division 42 – Process Heating, Cooling, and Drying Equipment. Process equipment plays a vital role in various industries, such as manufacturing, food processing, pharmaceuticals, and petrochemicals. The effective, efficient, and safe operation of process heating, cooling, and drying equipment is not only necessary for achieving desired results but also for maintaining a safe working environment and meeting industry requirements.

This guide will provide you with an in-depth understanding of the different types of heating, cooling, and drying equipment available, their applications, and the key factors to consider when selecting the most suitable equipment for a particular project. Moreover, we will emphasize the importance of energy efficiency, regular maintenance, and proper installation. We will also help you navigate through relevant safety and compliance issues associated with these types of equipment. Join us as we explore the world of process equipment through the lens of a construction specification expert, shedding light on:

- Introduction to CSI Division 42 – What it is and why it’s important

- Process Heating Equipment – Types, applications, and considerations

- Process Cooling Equipment – Types, applications, and considerations

- Process Drying Equipment – Types, applications, and considerations

- Selecting the Right Equipment – Evaluating performance, efficiency, and cost

- Safety and Compliance – Meeting industry standards and regulations

By the end of this guide, you will have a better understanding of the essential role process equipment plays in various industries and the crucial role construction specification experts have in selecting, maintaining, and ensuring the effective operation of this equipment. So, let’s dive in and unravel the complexities of CSI Division 42 – Process Heating, Cooling, and Drying Equipment!

Suggested Posts:

Maximizing Your Real Estate ROI: Tips and Strategies for Success

Understanding Construction Specifications: CSI Division 08 – Openings

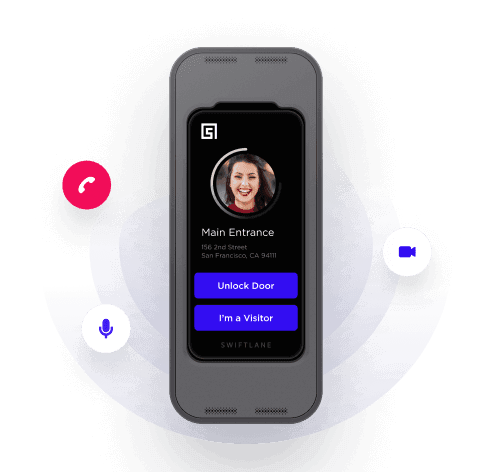

Residential Gate Access Control Systems – Complete Guide

Introduction to CSI Division 42

When it comes to the field of construction, there are several guidelines and standards that professionals must abide by to ensure the integrity, safety, and long-lasting quality of their projects. One such important standard is known as the Construction Specifications Institute (CSI) MasterFormat which contains numerous divisions, each comprising of unique categories. In this blog, we will delve deep into one of these divisions – CSI Division 42, which deals with Process Heating, Cooling, and Drying Equipment.

What is CSI Division 42?

CSI Division 42 focuses specifically on equipment and systems that help regulate temperature and humidity during industrial processes. These systems are paramount for maintaining the high-quality standards in various industries, as they play a crucial role in the production, manufacturing or processing of products. In essence, the right heating, cooling or drying equipment can ultimately determine the success or failure of a project or business.

Why is CSI Division 42 Important?

There are countless applications for Process Heating, Cooling, and Drying Equipment across industries that make it indispensable. For instance, the pharmaceutical, food and beverage, paper, and chemical industries rely on these systems for product manufacturing, preservation, and transportation processes. Within the construction industry, these systems may also be employed to create a controlled environment in buildings such as greenhouses, warehouses, and data centers. Consequently, construction specification experts must have a keen understanding of CSI Division 42 in order to provide valuable guidance on the selection, installation, and maintenance of these essential equipment systems. With the rapid advancement of technology and the changing needs of industries, it is crucial for these experts to stay up-to-date with industry standards, regulations, and best practices to ensure the long-term success and sustainability of projects.

CSI Division 42 and Compliance

Given the vital role these process heating, cooling, and drying equipment systems play across various industries, it is crucial to comply with the highest standards and regulations. This is where the role of construction specification expert becomes essential. These professionals not only assist with selecting the most suitable heating, cooling, or drying equipment but also ensure that their implementation adheres to relevant codes and regulations.

In summary, CSI Division 42 holds great importance in the realm of construction specifications, as it governs the standards and practices related to process heating, cooling, and drying equipment. A strong knowledge of this division not only aids in maintaining the high-quality standards of various industries but also helps ensure the safety, efficiency, and environmental sustainability of projects. Stay tuned for the following sections where we will discuss in-depth the various types of equipment and their applications, along with critical considerations in the selection process.

Process Heating Equipment – Types, Applications, and Considerations

In this section, we will dive into the different types of process heating equipment covered under CSI Division 42. Developing a deeper understanding of these systems is critical for construction specification experts aiming to select the best-suited equipment for a given project. By the end of this section, you will have a grasp on various types of heating equipment, their applications, and the factors to consider during the decision-making process.

Types of Process Heating Equipment

There are a range of process heating equipment types, including:

Boilers: These devices produce steam or hot water by heating water through fuel combustion or electric resistance. Boilers are widely used in industries such as power plants, food processing, and textile manufacturing.

Furnaces: Furnaces heat materials or products directly through fuel combustion or electric resistance. They are commonly employed in metal processing, glass manufacturing, and chemical production industries.

Heat Exchangers: Transfer heat from one medium to another without mixing the two. These systems are crucial components in various types of heating and cooling equipment, and can be found in power plants, manufacturing facilities, and HVAC systems.

Heat Transfer Equipment: This category includes systems such as thermal fluid heaters, which use a heated fluid to transfer heat to other mediums or processes. They are commonly used in chemical, pharmaceutical, and food processing industries.

Considerations When Selecting Process Heating Equipment

When selecting the most suitable process heating equipment for a project, several factors should be taken into account:

Efficiency: Choose equipment that offers optimized energy consumption and cost savings, as well as reduced emissions. High-efficiency systems may require a larger initial investment but often result in long-term benefits.

Capacity: Ensure the chosen equipment is capable of meeting the project’s heating demands. Oversizing or undersizing equipment could lead to reduced performance, increased energy consumption, and maintenance issues.

Installation: Proper installation is critical for optimal performance, efficiency, and safety. Work with experienced construction specification experts and adhere to industry best practices during installation.

Maintenance: Regular maintenance helps to prolong the life of the equipment and safeguard performance. Schedule routine inspections and adhere to the manufacturer’s guidelines for optimal results.

In conclusion, understanding the types of process heating equipment, their applications, and the factors to consider during selection is crucial for construction specification experts navigating CSI Division 42. Properly selecting, installing, and maintaining these systems can lead to increased efficiency, reduced operational costs, and a longer service life.

Process Cooling Equipment – Types, Applications, and Considerations

In contrast to process heating, process cooling equipment plays a vital role in maintaining controlled temperatures by removing excess heat from a process or environment. This section will explore the different types of cooling equipment available, their applications, and considerations when choosing the most appropriate solution for a given project. The topics of energy efficiency and the necessity for regular maintenance to ensure optimal performance will also be addressed.

Types of Process Cooling Equipment

There is a wide range of process cooling equipment to choose from depending on the specific requirements of a project. Below are some common types of process cooling equipment:

Chillers: Chillers are used to remove heat from a liquid, typically water or a water-glycol mixture. These systems can be either air-cooled or water-cooled and are utilized in various industries such as plastics, food and beverage, pharmaceuticals, and data centers.

Cooling Towers: Cooling towers are used to dissipate heat from a process or HVAC system through the evaporation of water. They are often employed in large-scale applications, such as power plants or large industrial facilities, due to their ability to handle high heat loads.

Refrigeration Systems: These systems use a refrigerant to absorb heat and then release it at a higher temperature. They are commonly used for cooling and preserving food, beverages, and pharmaceuticals.

Applications of Process Cooling Equipment

Process cooling equipment serves several industries, with the primary function being to remove unwanted heat from a process or environment. Some of the most common applications include:

Industrial Manufacturing: Process cooling equipment is essential for maintaining optimal operating temperatures in numerous manufacturing processes – from injection molding in plastic production to helping ensure consistent product quality in the food and beverage industry.

Data Centers: Cooling equipment is necessary in data centers to regulate the temperature and ensure the proper functioning of servers and other electronic equipment.

Medical Facilities: In healthcare settings, process cooling equipment is used to maintain proper temperatures for medical equipment, storage, and comfort cooling for patients and staff.

Considerations When Choosing Process Cooling Equipment

When selecting the most suitable cooling equipment for a project, several factors need to be considered:

Efficiency: Energy-efficient cooling equipment can result in significant cost savings over the long run. Therefore, it’s crucial to analyze the system’s efficiency when making a selection.

Capacity: The cooling capacity of a system should align with the specific requirements of the project. An undersized system can lead to poor temperature control and increased energy consumption, while an oversized system can result in higher initial and operational costs.

Maintenance: Regular maintenance is vital to ensure the optimal performance and longevity of cooling equipment. Be sure to consider the ease of access to components and the availability of replacement parts when selecting a system.

In conclusion, process cooling equipment plays a pivotal role in temperature regulation across a multitude of industries. By carefully considering the various types and applications of cooling equipment and paying close attention to efficiency, capacity, and maintenance requirements, the right system can be chosen to ensure a successful project outcome.

Process Drying Equipment – Types, Applications, and Considerations

Process drying equipment plays a crucial role in a variety of industries, including pharmaceutical, food and beverage, chemical, and more. In this section, we will examine different types of process drying equipment, their respective applications, and the factors that must be considered when selecting the most effective drying solution for your project. Additionally, we will emphasize the importance of energy efficiency and proper maintenance in ensuring the longevity and performance of process drying equipment.

Types of Process Drying Equipment

Air Dryers: These devices are designed to remove moisture from the air. They are commonly found in compressed air systems to prevent condensation and corrosion, but can also be used in various other applications, such as drying storage rooms or preventing mold in buildings.

Dehumidifiers: Similar to air dryers, dehumidifiers are used to reduce humidity levels in a designated area. They are often utilized in environments where maintaining low moisture levels is critical, such as pharmaceutical manufacturing, cleanrooms, and food storage facilities.

Spray Dryers: Primarily used in the food and pharmaceutical industries, spray dryers transform liquid solutions into dry powders by rapidly evaporating the liquid component using heated air.

Rotary Dryers: Commonly used in the mining, chemical, and agricultural industries, rotary dryers consist of a rotating drum that is heated from the outside to reduce the moisture content of materials. They are ideal for handling large volumes of materials and are highly energy-efficient.

Applications and Considerations

Selecting the right drying equipment depends on several factors, including the type of material, the required drying rate, and the desired final moisture content. It is essential to work closely with a construction specification expert to ensure that the chosen drying equipment meets project goals and requirements. Energy efficiency is a critical factor in drying equipment selection, as it can significantly impact operational costs. To optimize efficiency, consider the following factors:

Heat Recovery: Implementing heat recovery systems can recycle waste heat and reduce energy consumption by up to 50%.

Drying Temperature: Optimizing the drying temperature can minimize the energy required for evaporation while maximizing the drying rate.

Airflow: Properly designed airflow patterns can optimize drying performance and minimize energy consumption. As with any process equipment, proper installation and maintenance are critical to the longevity and performance of process drying equipment. Regular maintenance and inspections can help identify potential issues, such as leaks, corrosion, or component wear, and address them proactively to ensure that the equipment continues to operate efficiently and safely.

In conclusion, a thorough understanding of process drying equipment types and their applications is crucial for selecting the most appropriate solution for your project. Collaborating with a construction specification expert and considering factors such as energy efficiency and maintenance will assist in achieving the desired results while minimizing long-term costs and ensuring operational safety.

Selecting the Right Equipment – Evaluating Performance, Efficiency, and Cost

Choosing the right process heating, cooling, or drying equipment is a critical aspect of any construction project. When faced with this decision, it’s important to consider not only the equipment’s capabilities and applications but also its performance, energy efficiency, and cost. In this section, we will explore these factors in-depth and explain why working with a construction specification expert can ensure that you make the best equipment selections for your project.

Evaluating Performance

In order to select the most appropriate equipment for your project, you must first evaluate its performance. This involves assessing the equipment’s capabilities, such as its heating, cooling, or drying capacity, as well as its ability to maintain consistent temperatures and control humidity levels. You’ll also want to examine the equipment’s reliability and any potential limitations in terms of its size, weight, or power requirements. By thoroughly evaluating the performance of each option, you can better determine which piece of equipment is best suited to your project’s unique needs.

Energy Efficiency

Energy efficiency is a vital consideration when selecting process equipment, as it can have a significant impact on your project’s overall costs and environmental footprint. Highly efficient equipment may be more expensive upfront, but it can save you money in the long run by reducing energy consumption and lowering utility bills. Look for equipment that is ENERGY STAR certified or meets the efficiency requirements of relevant industry standards, such as ASHRAE, AHRI, or other regional regulations.

Cost Considerations

While performance and efficiency are essential factors, you must also take into account the cost of the equipment itself, as well as any installation, maintenance, or replacement costs that may be associated with it. Be sure to develop a comprehensive understanding of each option’s total cost of ownership so that you can weigh the long-term value of each piece of equipment against its upfront expense. Remember to also factor in any potential tax incentives or rebates for energy-efficient equipment, as these can help offset some of the initial costs.

Concluding Thoughts- Working with a Construction Specification Expert

As you navigate the complex process of selecting the right heating, cooling, or drying equipment for your project, it’s crucial to have the guidance and expertise of a construction specification expert. These professionals have a deep understanding of the various types of process equipment available, as well as the factors that should be considered when making equipment decisions. By working alongside a construction specification expert, you can ensure that your equipment choices not only align with your project’s goals and requirements but also offer the best return on investment for your project’s stakeholders.

In conclusion, selecting the most suitable heating, cooling, or drying equipment for your project requires careful evaluation of performance, efficiency, and cost. By considering these factors and working with a knowledgeable construction specification expert, you can make informed decisions that will contribute to the success of your project and the satisfaction of its stakeholders. Keep these considerations in mind as you plan your next construction project and take advantage of the benefits that come from selecting the right equipment.

Have Questions?

Get in touch with our team to learn more about what Swiftlane can do for you.