Welcome to our comprehensive guide on integrated automation in the construction industry! One of the most significant advancements in recent years has been the adoption of integrated automation systems, which hold the promise of transforming the built environment into smart, sustainable, and efficient spaces.

In this blog post, we will explore the various aspects of integrated automation, covering everything from components and technologies to design considerations, commissioning, and maintenance. We will also dive into practical examples and best practices, ensuring you gain valuable insights to successfully implement integrated automation in your construction projects. So, whether you are a seasoned professional or just beginning to explore the world of integrated automation, this guide is designed to be your go-to resource for understanding and embracing the future of construction. Let’s embark on this exciting journey and unleash the potential of integrated automation in the construction industry!

Suggested Posts:

Introduction to CSI MasterFormat and Division 01

Understanding CSI MasterFormat: Division 14- Conveying Equipment

Introduction to CSI Division 25 – Integrated Automation

Welcome to our comprehensive guide on the Construction Specifications Institute (CSI) MasterFormat system, with a special focus on Division 25 – Integrated Automation. In the era of rapidly advancing technology and increasing demand for sustainable buildings, integration, and automation play a crucial role in the construction industry. In this blog post, we will walk you through the significance of integrated automation and its various components, aiming to enhance your understanding of the subject and provide valuable insights for your construction projects.

MasterFormat is a standardized classification system used extensively in the construction industry to organize project manuals, specifications, and other construction documentation. The MasterFormat provides a consistent framework for organizing and communicating critical project information across various construction disciplines. Division 25 – Integrated Automation is instrumental in the design and implementation of smart, efficient, and sustainable buildings. With the growing importance of optimizing building performance, conserving energy, and prioritizing safety, the adoption of advanced automation technologies is ubiquitous in the contemporary construction landscape. Integrated automation systems, when implemented effectively, can help streamline processes, reduce operational costs, and improve overall building functionality.

Our blog post will cover the following essential topics related to Division 25:

- Components and Technologies of Integrated Automation

- Integration Techniques and Protocols

- Design Considerations for Integrated Automation

- Commissioning and Maintenance of Integrated Automation Systems

- Case Studies and Best Practices in Integrated Automation

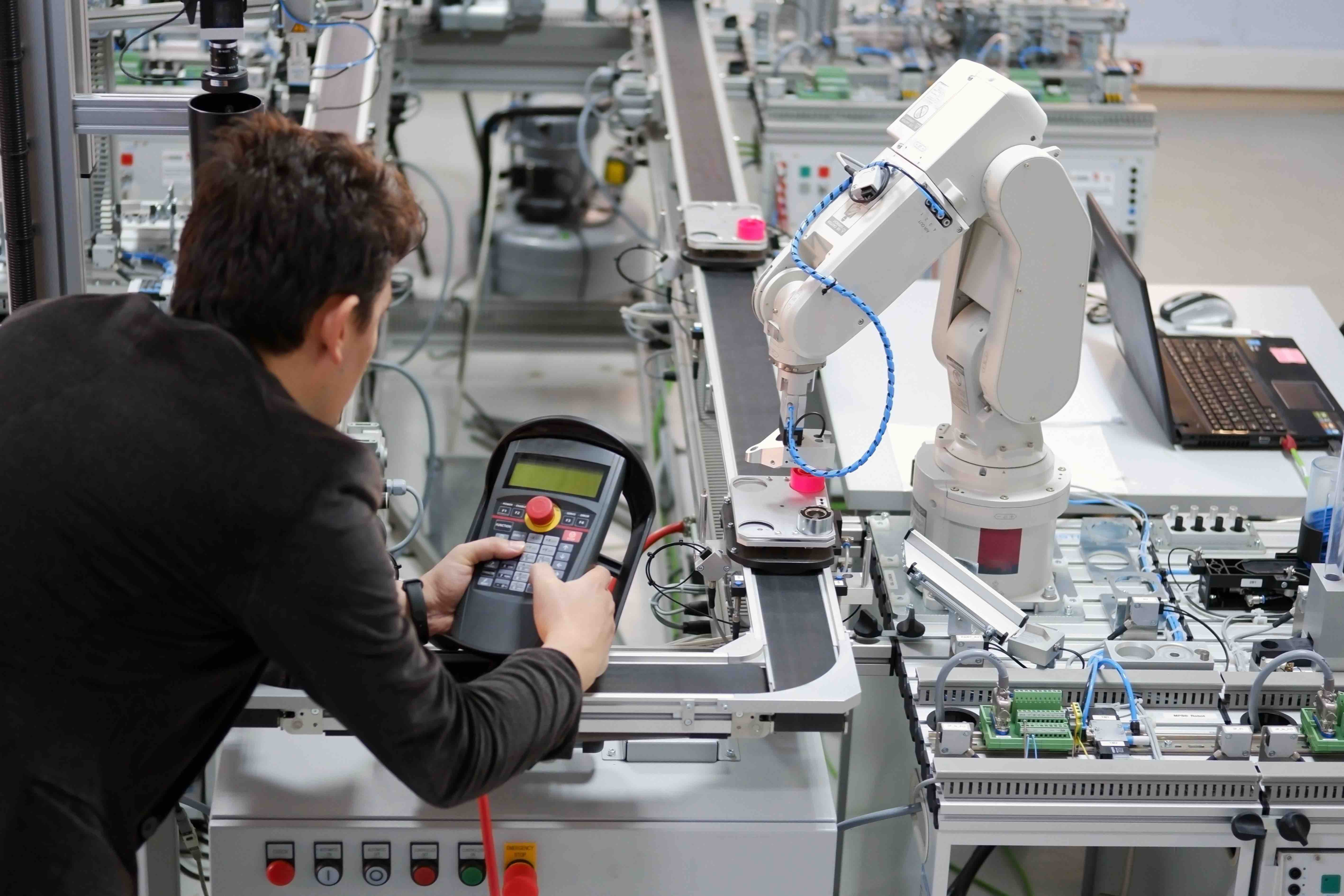

Components and Technologies of Integrated Automation

In this section, we will delve into various components and technologies that fall under CSI Division 25 – Integrated Automation. Understanding these components will help construction professionals design and implement advanced automation systems in their projects. Let’s explore the following subtopics:

Building Automation Systems (BAS)

A Building Automation System (BAS) is a centralized control platform that manages and monitors various building systems, such as HVAC, lighting, and energy usage. BAS can significantly improve the efficiency of building operations, reduce energy consumption, and enhance occupant comfort. With features like remote access and data analytics, BAS allows facility managers to make informed decisions regarding building performance and maintenance.

Energy Management Systems (EMS)

Energy Management Systems (EMS) focus on optimizing a building’s energy consumption by automating energy-saving measures, such as demand-based lighting and HVAC control. EMS can significantly reduce energy costs and contribute to the building’s sustainability goals. By integrating EMS with other building systems, facility managers can obtain a holistic view of the building’s energy performance and make data-driven decisions to improve efficiency.

Security and Access Control Systems

Effective security and access control systems are essential to ensure the safety and security of occupants and assets in a building. These systems encompass technologies like video surveillance, intrusion detection, and access control, which manage access points and prevent unauthorized entry. Integrating security systems with other building components, such as lighting and HVAC, helps create a safer and more efficient environment for occupants.

Fire and Life Safety Systems

Fire and life safety systems are critical in protecting building occupants and minimizing property damage in the event of an emergency. These systems include fire detection, alarm/notification, and suppression components, which can be integrated with other building systems for a more comprehensive and coordinated response in emergencies. For example, an integrated system can automatically shut down HVAC systems, close fire-rated doors, and initiate emergency lighting during a fire event.

In conclusion, integrated automation technologies play a vital role in enhancing building performance, safety, and efficiency. As the demand for smart and sustainable buildings continues to grow, construction professionals must stay up-to-date with these technologies and effectively incorporate them into their projects. In the following sections, we’ll discuss integration techniques and protocols, design considerations, commissioning and maintenance, as well as case studies and best practices in integrated automation. So, stay tuned!

Integration Techniques and Protocols

In this section, we will delve into the various integration techniques and communication protocols that are crucial for the seamless implementation of integrated automation systems in construction projects. Creating a well-coordinated and high-performing automation system requires the ability of different systems and devices to communicate and work together effectively. This is where interoperability and integration techniques come into play.

Interoperability and Integration Challenges

Interoperability is vital for the success of an integrated automation system, as it enables the communication between different systems, devices, and applications, regardless of the manufacturer. However, the construction and automation industry faces several challenges in achieving seamless integration, primarily due to the use of multiple proprietary technologies and a lack of standardized protocols.

Open Protocols

Fortunately, various open communication protocols have been developed to address the issue of interoperability. These protocols allow devices and systems from different manufacturers to communicate seamlessly and facilitate the smooth sharing of data and control commands. Some of the most widely used open protocols in the automation industry include:

BACnet: An industry-standard protocol specifically designed for building automation and control systems, BACnet is a popular choice for HVAC, lighting, and access control systems. Its widespread adoption makes it a suitable option for most construction projects.

KNX: Another versatile and widely used open protocol, KNX is suitable for a variety of applications, including HVAC, lighting, security, and energy management systems. KNX systems can be easily configured, enabling simple integration with other automation systems.

LonWorks: Developed by Echelon Corporation, LonWorks is a versatile protocol that supports various control and automation applications. LonWorks is used in large-scale projects, such as airports and stadiums, due to its robustness and reliability.

Proprietary Protocols

In addition to open protocols, many manufacturers develop proprietary communication protocols specific to their devices and systems. While these protocols may offer advantages in terms of performance and customization, they can pose challenges when integrating with systems from different manufacturers. Therefore, thorough research and evaluation should be done when selecting a system or device that relies on proprietary protocols.

The Role of the Internet of Things (IoT)

The Internet of Things (IoT) has revolutionized the way different systems and devices communicate with each other, offering seamless integration and data sharing among various building systems. IoT-enabled devices collect and transmit real-time data, facilitating improved decision-making and enhanced efficiency of building automation systems. The widespread adoption of IoT technologies is expected to further improve the performance and capabilities of integrated automation systems in the future.

In conclusion, understanding the various integration techniques and communication protocols is crucial for the successful deployment of an integrated automation system. Construction professionals and integrators should be well-versed in these technologies to make informed decisions and ensure that their projects benefit from the full potential of automation.

Design Considerations for Integrated Automation

When planning and implementing integrated automation systems in construction projects, it is essential to consider several key design aspects. This section will discuss major design considerations, including system scalability, flexibility, redundancy, and alignment with energy efficiency and sustainability goals.

System Scalability

Scalability is a critical aspect to consider during the design process, as it ensures that the integrated automation system can accommodate future expansions, upgrades, or changes in building needs. To achieve this, choose automation technologies that are modular and easily expandable, allowing seamless integration of new components or systems as they are added. Moreover, ensure that the communication network has sufficient bandwidth and capacity to support growth without sacrificing system performance.

Flexibility and Redundancy

Flexibility is crucial in integrated automation design as it enables the system to adapt to evolving building requirements, occupants’ needs, and advances in technology. Opt for open protocols, such as BACnet, KNX, or LonWorks, that facilitate interoperability between different devices from various manufacturers. This approach fosters a more accessible and adaptable environment for system integration, making it easier to incorporate new features or replace outdated components. Redundancy is another important design consideration, ensuring continuous operation and minimizing potential downtime. Plan for redundant communication paths, power supplies, and control devices to maintain functionality in case of hardware failures or network issues.

Energy Efficiency and Sustainability

Incorporating energy efficiency and sustainability goals during the design process is essential to create smart, environmentally responsible buildings. Some strategies to consider include:

Implementing an energy management system (EMS) to optimize energy consumption, monitor real-time data, and enable proactive adjustments in building operations.

Selecting automation technologies that support demand-response strategies, such as integration with utility grid signals or utilizing renewable energy sources.

Incorporating daylight harvesting and occupancy sensors to optimize lighting and HVAC systems based on occupancy patterns. When selecting automation technologies, assess their long-term energy-saving potential, and ensure they align with the project’s sustainability objectives.

In conclusion, thoughtful design considerations play a vital role in determining the overall success of integrated automation systems in construction projects. By prioritizing system scalability, flexibility, redundancy, and alignment with energy efficiency and sustainability goals, you can create a robust and reliable integrated automation system that optimizes building performance for years to come.

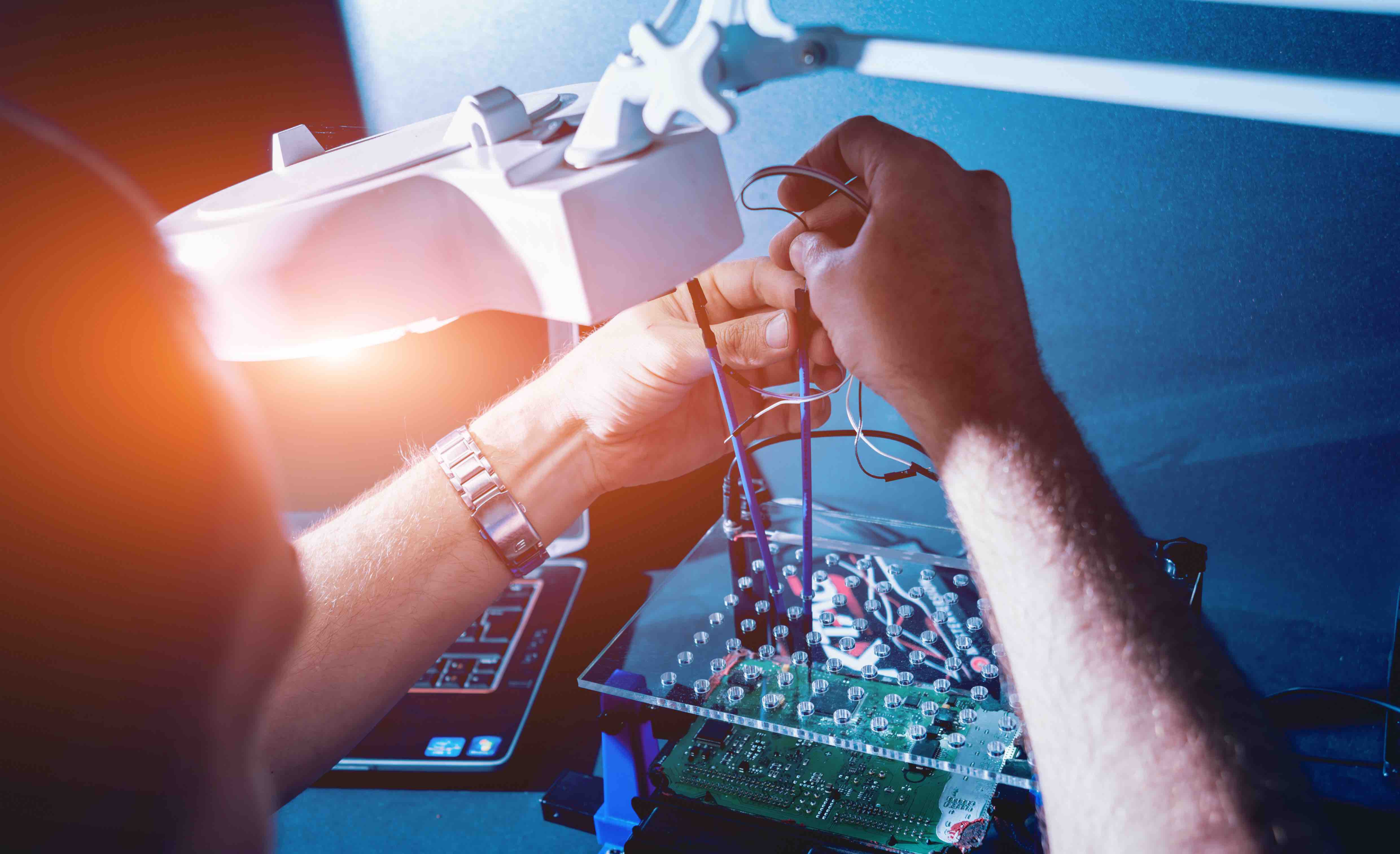

Commissioning and Maintenance of Integrated Automation Systems

In this section, we will delve into the crucial aspects of commissioning and maintaining integrated automation systems in construction projects. Ensuring an efficient and effective system is not only about selecting the right technology and design, but also about proper commissioning and regular maintenance.

Commissioning

Successful commissioning is vital for verifying that all components and systems are functioning optimally and are well-integrated with each other. This process should be carried out by a qualified commissioning agent who can ensure that the integrated automation systems are installed as per the design specifications and meet all the performance requirements. A robust and thorough commissioning process typically consists of the following stages:

Pre-functional testing: This involves the initial inspection and testing of individual components to identify any defects or issues.

Functional testing: After pre-functional testing, the integrated automation system should be tested as a whole to ensure seamless operation and interoperability between the various systems.

Performance verification: This step involves assessing the overall performance of the integrated automation system to make sure it aligns with the energy efficiency and sustainability goals set during the design process.

Maintenance

Once the integrated automation system is commissioned, ongoing maintenance is essential to ensure system reliability and performance. This includes regular updates and upgrades to keep up with advances in technology and evolving industry standards. Keeping an eye on the maintenance requirements of the various automation systems helps identify potential issues early on and can prevent costly repairs and downtime in the long run. Creating a comprehensive maintenance plan is essential to extend the life of the integrated automation system and maximize return on investment. Some tips for developing an effective plan include:

Establishing a regular maintenance schedule: This ensures that the systems are checked and updated periodically, and helps minimize the risk of unforeseen breakdowns.

Monitoring system performance: Regularly monitoring the performance and energy use of the integrated automation system can provide valuable insights into areas that need improvement or optimization.

Training and support: Investing in training for building staff and providing access to ongoing technical support can help maintain the optimal functioning of the integrated automation system over its lifecycle.

Conclusion

Incorporating integrated automation systems in construction projects not only enhances efficiency, safety, and building performance, but also provides long-term benefits in terms of energy savings and sustainability. Proper commissioning combined with regular maintenance will ensure the reliability and effectiveness of these systems, ultimately resulting in a higher return on investment for construction professionals.

Upgrade Your Building Security

Get in touch with a Swiftlane specialist for more information on the best access control and video intercom solution for your building.